Thunder roars, the sky darkens, and then, with a blinding flash, the bolt strikes. Lightning, a powerful force of nature, can wreak havoc in an instant. While we often focus on staying safe during a storm, the aftermath of a lightning incident requires careful attention. Today, we’ll explore what to do after a lightning strike to ensure the safety of yourself, your belongings, and your property.

- Prioritize Safety First:

After the lightning has struck, the immediate concern is safety. If you are outdoors, seek shelter immediately. If you are indoors, stay away from windows, and doors, and avoid using electrical appliances or plumbing fixtures. It’s essential to wait for a safe amount of time after the storm has passed before venturing outside.

- Check for Injuries:

Assess yourself and those around you for any injuries. If someone is injured, seek medical attention promptly. Lightning strikes can cause various injuries, ranging from burns to cardiac issues. Even if injuries seem minor, it’s advisable to consult with a healthcare professional.

- Inspect Your Home:

Lightning can cause structural damage to buildings. Inspect your home for signs of damage, such as cracks in walls, damage to the roof, or visible burn marks. If you suspect structural damage, it’s crucial to consult with a professional to assess the extent of the issues.

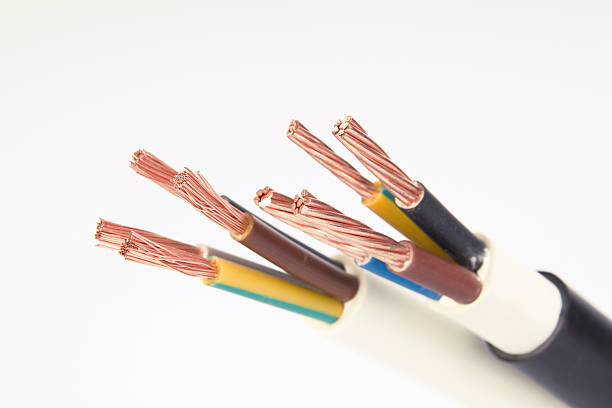

- Evaluate Electrical Systems:

Lightning can surge through electrical systems, potentially damaging appliances and creating fire hazards. Inspect your electrical systems, including outlets, switches, and circuit breakers. If you notice any burning smells, sparks, or other signs of damage, it’s imperative to turn off the power and contact an electrician.

- Assess Electronic Devices:

Lightning can wreak havoc on electronic devices, from computers to home entertainment systems. Check all electronic devices for damage. Unplug them and assess for any signs of burns, melting, or other abnormalities. It’s advisable to have a professional inspect and repair damaged electronics.

- Inspect Trees and Landscaping:

Lightning can cause damage to trees, sometimes resulting in falling branches or weakened structures. Inspect your property for any signs of damage to trees or landscaping. Address any potential hazards promptly to prevent accidents or further property damage.

- Document the Damage:

Take photographs and make notes of any damage caused by the lightning strike. This documentation can be valuable when filing insurance claims. Be thorough in capturing the extent of the damage both inside and outside your home.

- Contact Your Insurance Provider:

If you have homeowner’s insurance, contact your insurance provider as soon as possible. Provide them with a detailed account of the incident and the documentation you’ve gathered. This will expedite the claims process and help you recover from the financial impact of the lightning strike.

Experiencing a lightning incident can be a harrowing event, but knowing what steps to take afterward is crucial for your safety and recovery. By prioritizing safety, thoroughly inspecting your surroundings, and documenting the damage, you can navigate the aftermath of a lightning strike with a clearer understanding of what needs to be done. Remember, seeking professional assistance when needed ensures a comprehensive recovery process.

Recent Comments